Ordnance of the Week: YaRM Anti-Landing Mine

Background and Purpose

The recent destruction of the Kakhovka dam in Ukraine has resulted in the uncovering and displacement of potentially thousands of landmines and anti-amphibious mines used in and along the Dnipro River. Among the most hazardous of these mines is the YaRM anti-landing mine.

Image of YaRM mine from open source, posted to LinkedIn by Hadj Boudani.

The YaRM mine is normally emplaced in shallow waters of coastal areas, beaches, and banks of rivers and lakes to counter landing craft and other amphibious vehicles. With it’s built-in anchoring mechanism, the mine can be emplaced in water between 1 and 12 meters in depth, usually by a small boat. The mine is designed to then float beneath the surface between 0.1 to 0.3 meters deep. (1)(3)

Engineering Ammunition: Material Guide Parts and Applications Book One, Military Publishing House, Moscow 1976. (colorized)

When the cruciform (cross) rod atop the mine receives a force of 0.6-0.9 kilograms, the main charge explodes. The intent is to rip a hole in the underside hull of the target vessel. (1) The mine is designed to remain in its position in a current up to 1 meter/second. (1) The significant flooding caused by the Kakhovka dam destruction has likely unmoored many YaRM mines from their emplaced positions along the banks of the Dnipro and will deposit them in unexpected and potentially very dangerous locations. It is also highly probable that this has caused mines to detonate upon impact with other objects in areas affected by the flood.

Basic Identification Information

Diagram from Iraq Ordnance Identification Guide, US Department of Defense, January 2004

The YaRM mine is 275mm in diameter, 510mm in height with the anchor portion, and a total of 900mm in height with the cruciform tilt rod attachment. (2) It has a welded metal body, with the weld easily visible in photographs. The standard Soviet-era YaRM is painted grey with black stenciled markings, although there can be many variations. The cylindrical anchor also has a carrying handle.

When deployed, you can see along the bottom portion of the mine a conical section in which the main charge is housed, along with the cable attachment to the anchor section. This image of a demonstration model of a YaRM shows the separate components.

Image of a demonstration model of the YaRM, photo collection of D.I. Gorbovksy

Due to the typical location of emplacement of YaRM mines, they will suffer weathering and corrosion over time, and the paint and markings may not be easily visible. This open-source photo from social media purportedly shows a YaRM recently found along the banks of the Dnipro, covered in foam from the river.

Image posted to LinkedIn by Sean Moorhouse

YaRM mines have also been found in the last year floating in the Black Sea and near the Bosporus (4).

Components

The YaRM is made up of several key components:

· The body of the mine holds the main charge in a conical section in the lower portion and a large volume of empty space for buoyancy. (3)

· At the top of the main body is the fuze well, which houses the VRM striker-release fuze (2)

· Atop the fuze sits the cruciform tilt-rod which initiates the fuze firing. (1)

· Beneath the body of the mine is the cylindrical anchor which houses a wire reel attached to the bottom of the mine body. (1)(3)

Cutaway image from Ordnance and Munitions: The XXI Century Encyclopedia, Russia’s Arms and Technologies, Russian Ministry of Defense, February 1999

The full weight of the mine is 13 kilograms, with a main charge of 3 kilograms of TNT (1), plus the primer and detonator in the VRM fuze bringing the net explosive weight of the mine to 3.03 kilograms. (2)(3)

Fuze Arming and Functioning

Diagram from Military Engineering Training, Military Publishing House of the USSR Ministry of Defense, 1982.

The YaRM is made ready for emplacement first through the installation of the VRM in the fuze well and the attachment of the cruciform tilt-rod. The safety ring is then removed, the anchor made ready, and the mine is released into the water. The anchor deploys, eventually placing the mine at the desirable depth, during which time the fuze arming process begins. (3)

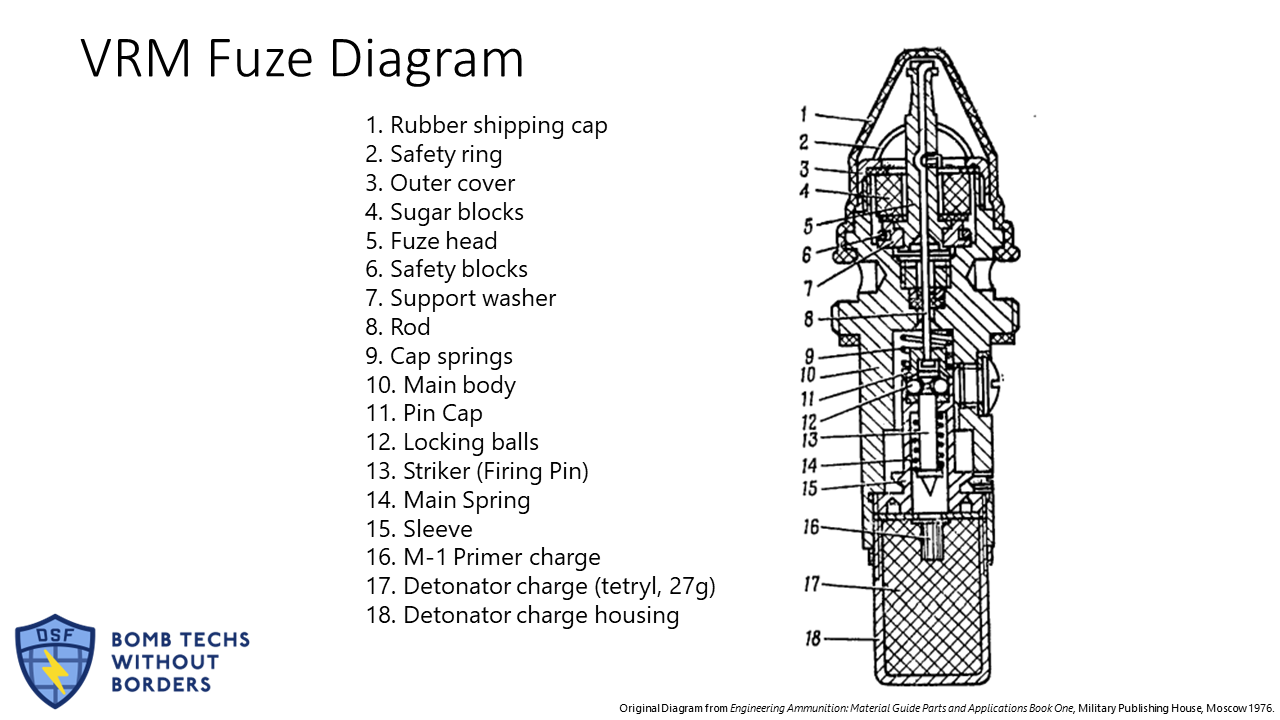

As noted in the fuze diagram above, additional safety blocks 6 are held in place with blocks made from sugar 4, which slowly dissolve in the water. The sugar takes between 10-40 minutes to dissolve depending on water temperature, with colder water taking longer. (3)

The dissolving of the sugar blocks allows for movement of a central rod 8 which is attached to a cap 11 above the striker 13. The striker is held in position by two locking balls 12. (3)

When the cruciform tilt-rod is struck by a target with 0.6-0.9 kilograms of force, the central rod 8 is drawn upwards by the deflection of the tilt-rod, pulling the cap 11 and squeezing the cap springs 9. The pressure displaces the locking balls 12, releasing the striker 13 which is driven by the main spring 14 into the M-1 detonator 16. The detonating charge 17 explodes, thereby also exploding the main charge of 3 kilograms of TNT in the mine. (3)

Safety Precautions

The components of the YaRM are entirely mechanical, and there is no known self-neutralization feature, nor any built-in anti-tampering device. The mine is therefore capable of lying in wait for a target for many years if otherwise undisturbed. The striker-release nature of the VRM fuze demands extreme caution from EOD operators, particularly when encountering an item that has been displaced from its original position.

You can find identification reference data for the YaRM and other mines in our published Basic Ammunition Identification Guide for Ukraine (both Ukrainian and English editions) hosted by Bulletpicker LLC.

Sources:

(1) Ordnance and Munitions: The XXI Century Encyclopedia, Russia’s Arms and Technologies, Russian Ministry of Defense, February 1999.

(2) Iraq Ordnance Identification Guide, US Department of Defense, January 2004.

(3) Engineering Ammunition: Material Guide Parts and Applications Book One, Military Publishing House, Moscow 1976.

(4) “UK MoD: Mines in Black Sea are “Almost Certainly” of Russian Origin,” The Maritime Executive, 03 April 2022.

(5) Military Engineering Training, Military Publishing House of the USSR Ministry of Defense, 1982.